Argentona – Canmartex, owner of the Jumberca brand of circular knitting machines, and its partner Eurecat, have launched a new “Aracne” company that commercializes digital technology using Artificial Intelligence (AI) and other Industry 4.0 innovations and allowing the production of circular knitting fabrics with zero defects.

Aracne is described as a new commercial initiative focused on research and development and which objective is to deploy and sell advanced technological solutions that meet the specific challenges of the textile sector, in particular knitting sector. The proposed solutions are modular and can be integrated with other equipment.

The technology developed is anchored at the heart of Industry 4.0 and is inspired by current challenges, allowing textile companies to improve their production processes while improving product quality and reducing environmental impact.

Knitting is a particular sub-sector in terms of process

As Aracne points out, the knitting value chain is multi-process without a large horizontal integration between them (knitting, dyeing, cutting and manufacturing). The large majority of equipment or machines is autonomous and operates at very high production rates.

However, these different machines are not communicating, they do not exchange any data between them (neither parameters, nor results). Manufacturing today works as follows: the output of each process is simply the input of the next process.

The condition of the equipment influences the quality of the fabric produced

When equipment does not work as it should, it can affect the final product (the fabric) resulting in minor or major defects such as holes, streaks, stains… defects that are currently only detected at the end of the process, during the fabric inspection step.

The machines used in knitting include sensors to detect problems such as needle or platinum breakage, loss of thread tension or other, but maintenance remains curative in this case.

However, as Canmartex notes, predictive or preventive maintenance is now the only way to ensure the proper functioning of equipment.

How does defect detection work?

Currently, fabric inspection is performed either manually (by experts who check the fabric using specific protocols) or automatically (with automated systems based on artificial vision). The defects found are thus identified and isolated in order to avoid the use of this part of the fabric during the manufacturing process.

According to Canmartex, this solution is extremely inefficient and non-viable since problems are only identified after production. It is also unreliable because visual inspection is often defective and defects can go undetected.

The textile industry, and especially the knitting sector, is aware of the need to improve its processes, making them more efficient and minimizing its environmental impact. Industry 4.0 is currently its best solution, even if it is not easy to deploy in a sector dominated by analog.

Aracne’s innovation

It is true that there are intelligent systems on the market today using AI to detect fabric defects and that are able to interpret the origin of the problem and interact with the machine almost in real time. However, these systems remain responsive.

Aracne’s solutions are predictive, that is, they are able to analyze the quality of key equipment components to accurately predict potential manufacturing defects even before the operation is launched.

These innovative technological solutions are compatible with Industry 4.0 and “will undoubtedly revolutionize textile production in the near future and enable it to comply with the requirements of a sustainable industry,” according to the company.

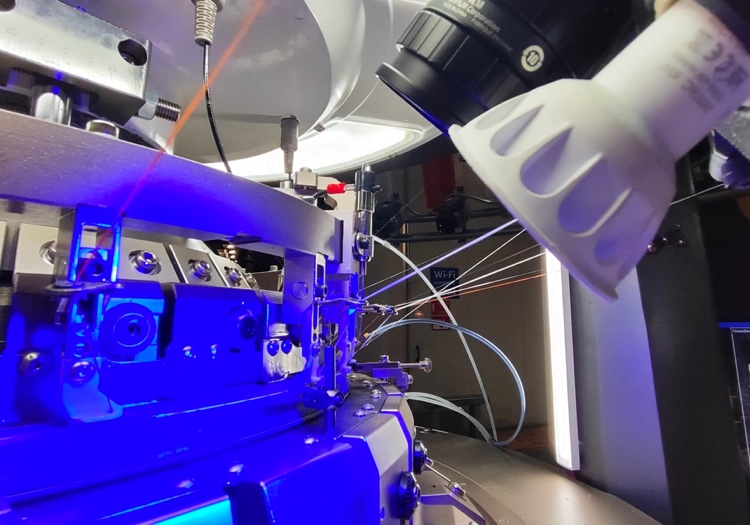

According to Canmartex, Aracne uses “state-of-the-art photonic and IoT systems coupled with AI algorithms and its experts’ extensive textile industry knowhow to identify these problems report them non-intrusively to the production manager or operator and pre-empt faulty manufacturing.” The company adds that its team is currently working on several areas of machine detection and on a global solution called «Fabric Brain Solution»

The proposed technology monitors the quality of the needles and sinkers and reports in real time any malfunctions or deterioration. The goal is to achieve zero manufacturing defects.

Xavier Plantà, Technical Director of Aracne, explains ““The key difference with respect to other technologies already on the market is that Aracne’s technology is a predictive system which anticipates defects by harnessing photonic and Internet of Things systems coupled with artificial intelligence algorithms which predict potential manufacturing faults before the fabric is made.”

Source: https://www.knittingtradejournal.com/circular-knitting-news/15607-new-firm-created-to-deliver-defect-free-knits